1. Industry overview and market demand

Gas hob enamel pan support, or gas hob enamel pan support, is an indispensable and important component in modern kitchens. With the improvement of modern people's living standards, consumers have put forward higher requirements for the functionality, aesthetics and safety of kitchen appliances. As the core equipment of the kitchen, the design and performance of gas stoves directly affect the daily cooking experience. Due to its unique material and craftsmanship, enamel pot racks provide excellent high temperature resistance, easy cleaning, corrosion resistance and other properties, and have become the first choice of many high-end gas stove brands.

In recent years, the rapid development of the global kitchen utensils market has brought huge market opportunities to the gas stove enamel pot rack industry. According to market research reports, the annual growth rate of the global kitchen utensils market is approximately 5%, and enamel pot racks, as an important part of it, have seen particularly significant growth in demand. Especially in Asia and Europe, the market share of enamel pot racks continues to expand due to the rich culinary culture and increasing demand for high-quality kitchenware. In China, with the advancement of urbanization and the rise of the middle class, consumer demand for high-end kitchen supplies continues to grow, further promoting the development of the enamel pot rack market.

Environmental protection and health factors have also become important considerations affecting consumer choices. Because enamel pot racks do not contain harmful substances and cause less environmental pollution during the production process, they are in line with modern people's pursuit of healthy and environmentally friendly life concepts. Compared with traditional stainless steel or cast iron pot racks, enamel pot racks not only improve performance, but are also more beautiful in appearance and design, meeting consumers' dual needs for fashion and quality.

From the perspective of industry competition, the enamel pot rack market is also showing fierce competition. Major brands strive to win the favor of consumers through continuous innovation and improvement of product quality and functionality. In the future, with the advancement of technology and the improvement of production processes, the performance and cost-effectiveness of enamel pot racks will be further optimized, injecting new impetus into the development of the industry.

2. The production process and technological innovation of enamel pot racks

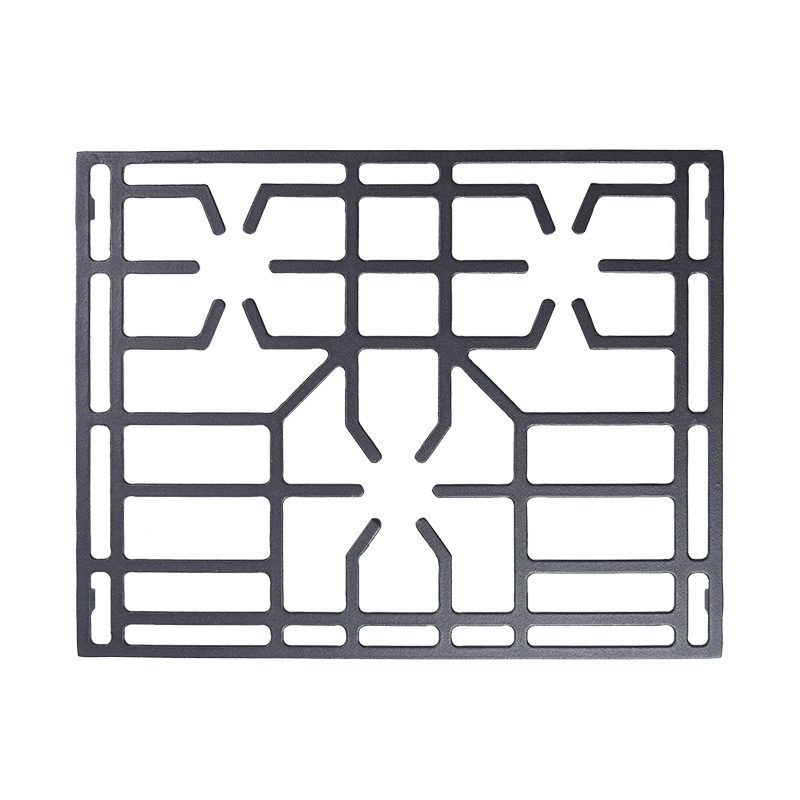

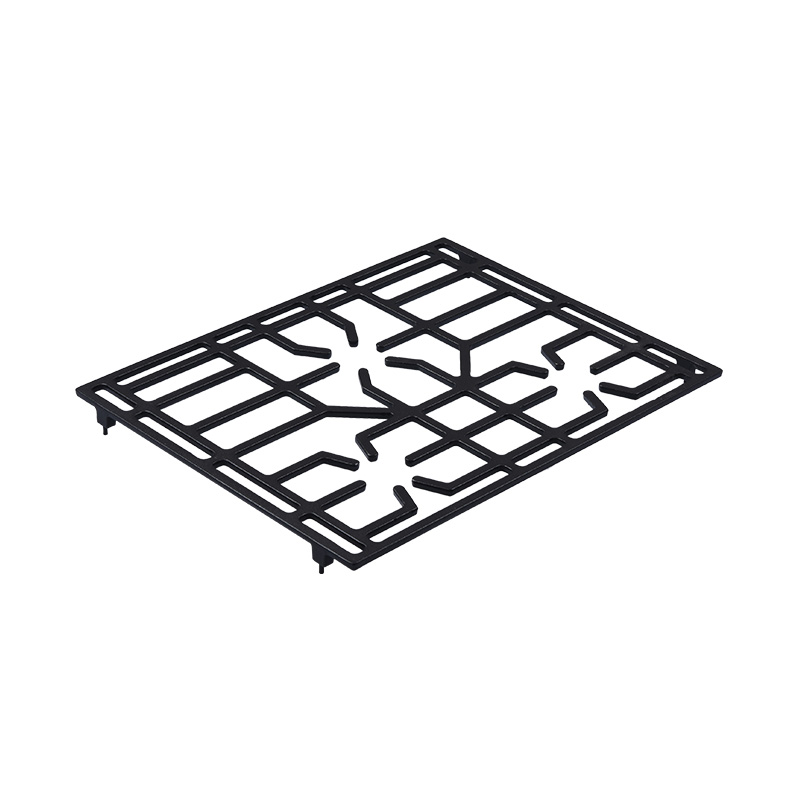

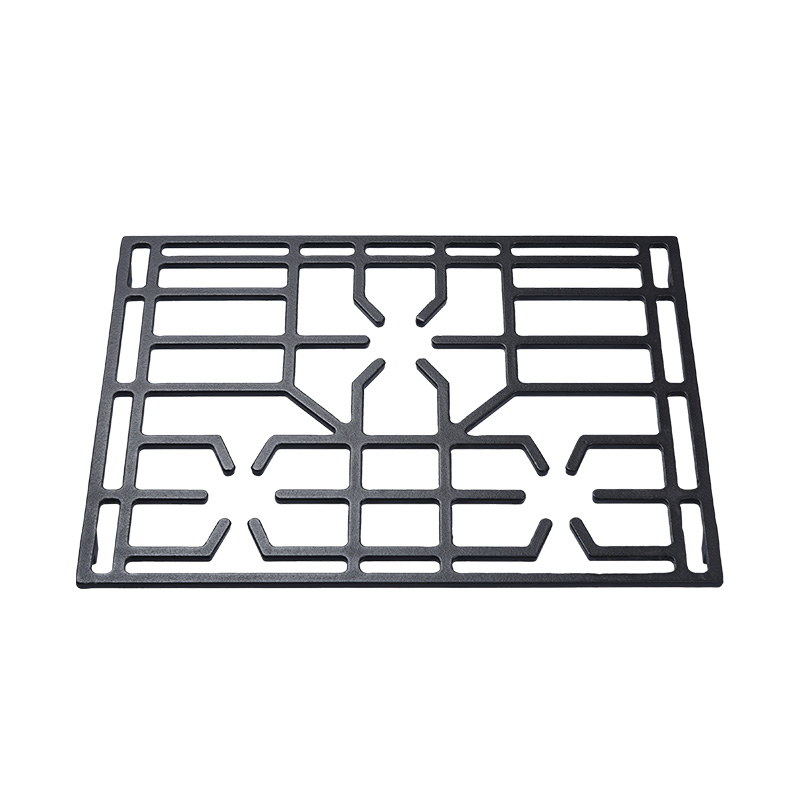

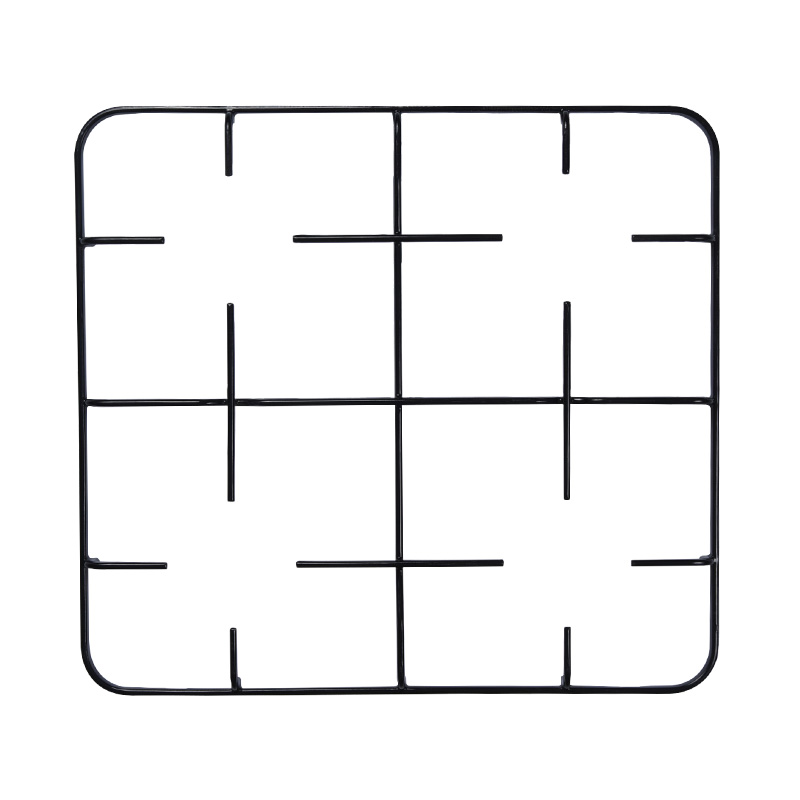

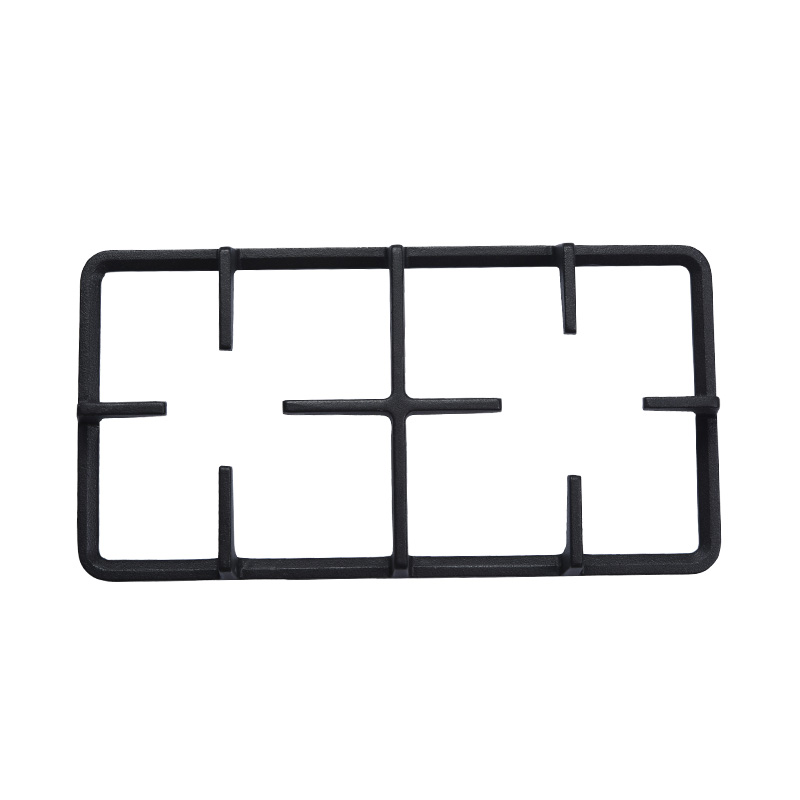

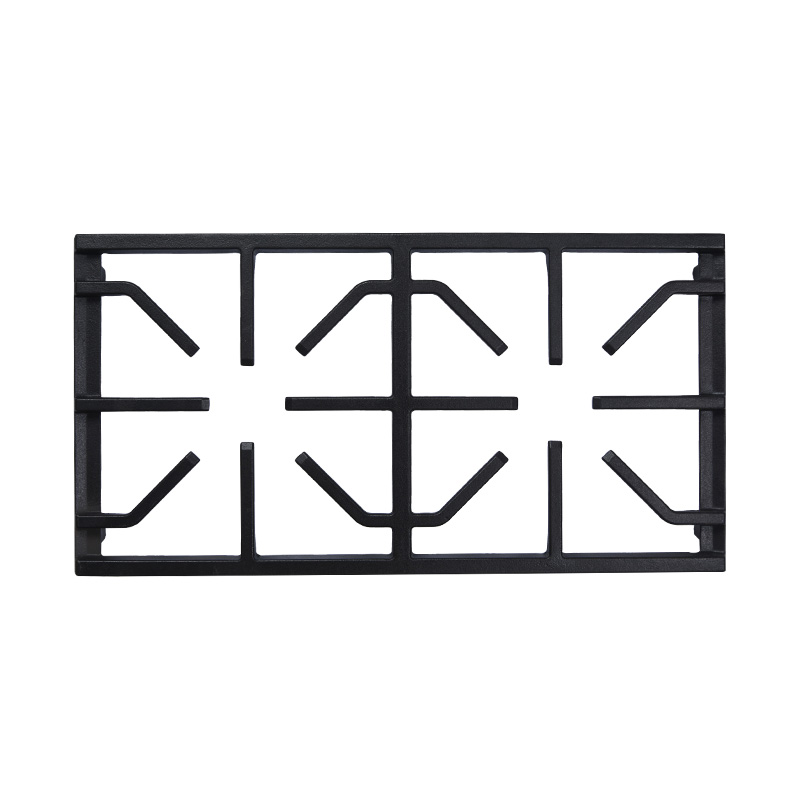

The production process of enamel pot racks is complex and delicate, involving multiple key steps, including raw material selection, casting, enamel coating and high-temperature firing. Each link requires precise control and high-standard quality management to ensure the excellent performance and beautiful appearance of the final product.

The selection of raw materials is the basis for making high-quality enamel pot racks. Generally speaking, high-quality cast iron or steel is the main raw material. These materials have good mechanical properties and high temperature resistance, and can maintain stable structure and performance under high temperature environment. During the casting process, the raw materials are processed into a pot rack of a specific shape through precision casting technology, and the surface is treated to improve the adhesion of the enamel coating.

The enamel coating process is the most critical step in the entire production process. The enamel coating is made by evenly coating the enamel slurry on the surface of the pot rack, and then firing it at a high temperature of 800℃ to 900℃ to make the enamel layer firmly bonded to the substrate, thereby forming a smooth and durable surface. The enamel coating not only provides excellent high temperature resistance, but also has excellent corrosion resistance and easy cleaning characteristics. The advancement of modern technology has significantly improved the performance of enamel coatings. For example, by adding nanomaterials, the hardness and wear resistance of the enamel layer are improved, thereby extending the service life of the pot rack.

Technological innovation is an important driving force for the development of the enamel pot rack industry. In recent years, the introduction of automated production lines has greatly improved production efficiency and product consistency. Automated equipment can accurately control the thickness and uniformity of the enamel coating and reduce the impact of human factors on product quality. In addition, automated production lines can also perform real-time monitoring and quality inspection to ensure that each batch of products can meet strict quality standards.

Environmental protection technology is also increasingly used in the production of enamel pot racks. The use of environmentally friendly materials and green manufacturing processes to reduce harmful emissions during the production process meets the requirements of modern society for sustainable development. For example, the development of non-toxic and harmless enamel materials reduces pollution to the environment while ensuring the health and safety of consumers. These technological innovations not only improve product quality, but also enhance the market competitiveness of enterprises.

3. Application and future development trends of enamel pot racks

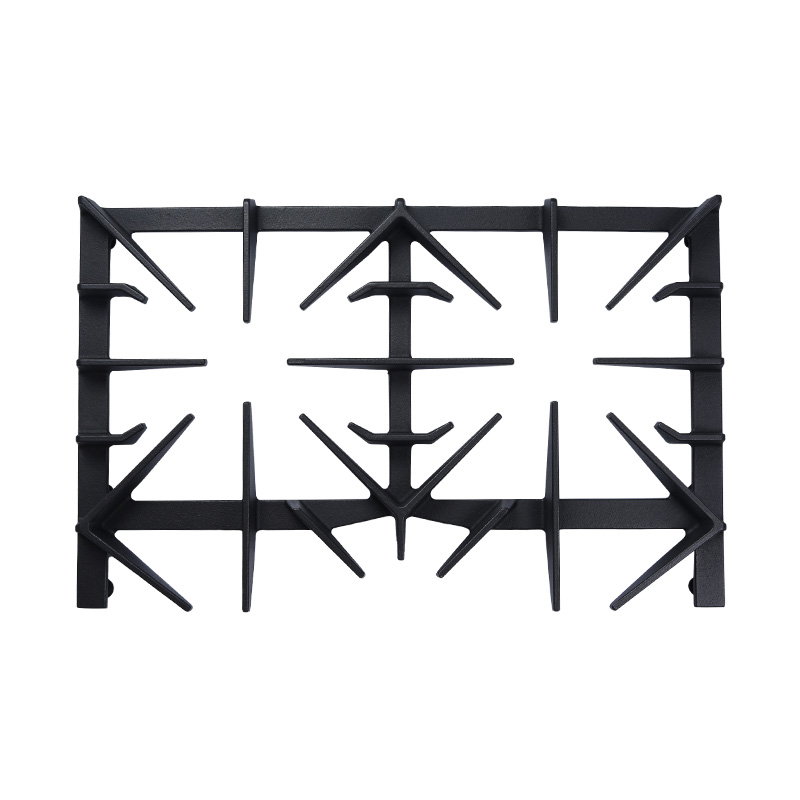

Enamel pot racks are widely used in household and commercial gas stoves. They are deeply loved by consumers and kitchenware manufacturers for their excellent heat resistance, durability and aesthetics. In household gas stoves, enamel pot racks not only improve the safety and convenience of cooking, but also add a fashionable element to the kitchen. The smooth surface and diverse color options of enamel pot racks enable them to perfectly match various kitchen decoration styles, meeting consumers' dual needs for beauty and practicality.

In commercial kitchens, enamel pot racks are an ideal choice for professional chefs because of their durability and easy-to-clean characteristics. Commercial kitchens are usually used frequently and have extremely high requirements for the durability and cleanliness of kitchen equipment. The high hardness and wear resistance of enamel pot racks can withstand long-term high-temperature cooking and frequent use. And its smooth surface makes cleaning easier, which helps to maintain the hygienic environment of the kitchen and improve work efficiency.

The market prospects of enamel pot racks are still broad. With the enhancement of environmental awareness and the development of green manufacturing technology, enamel pot racks will develop in a more environmentally friendly and sustainable direction. For example, research and development of new non-toxic and harmless enamel materials to reduce environmental pollution during the production process. In addition, with the continuous advancement of technology, the functionality and design of enamel pot racks will continue to improve, such as adding anti-slip design, improving the stability of pot racks, or adding smart sensors to achieve smart cooking control.

Personalized customization services will become a new highlight of the market. Modern consumers pay more and more attention to personalization and uniqueness. The customization service of enamel pot racks can provide diversified design and color options according to the needs of consumers to meet the personalized needs of different consumers. For example, enamel pot racks of different sizes, shapes and colors are provided to consumers, and they can even be customized according to specific kitchen decoration styles. This not only increases the added value of the product, but also enhances the competitiveness and market appeal of the brand.

With the popularization of smart homes, the combination of enamel pot racks and smart gas stoves will become a future development trend. Smart gas stoves can monitor the cooking status in real time through sensors and intelligent control systems, and automatically adjust the firepower and cooking time. As an important component of the gas stove, the design and function of the enamel pot rack will also be closely integrated with intelligent technology to achieve an intelligent cooking experience. For example, by embedding smart sensors on the enamel pot rack, the temperature and position of the pot can be monitored, the heating efficiency of the gas stove can be optimized, and the cooking effect can be improved.

English

English 中文简体

中文简体 Español

Español русский

русский